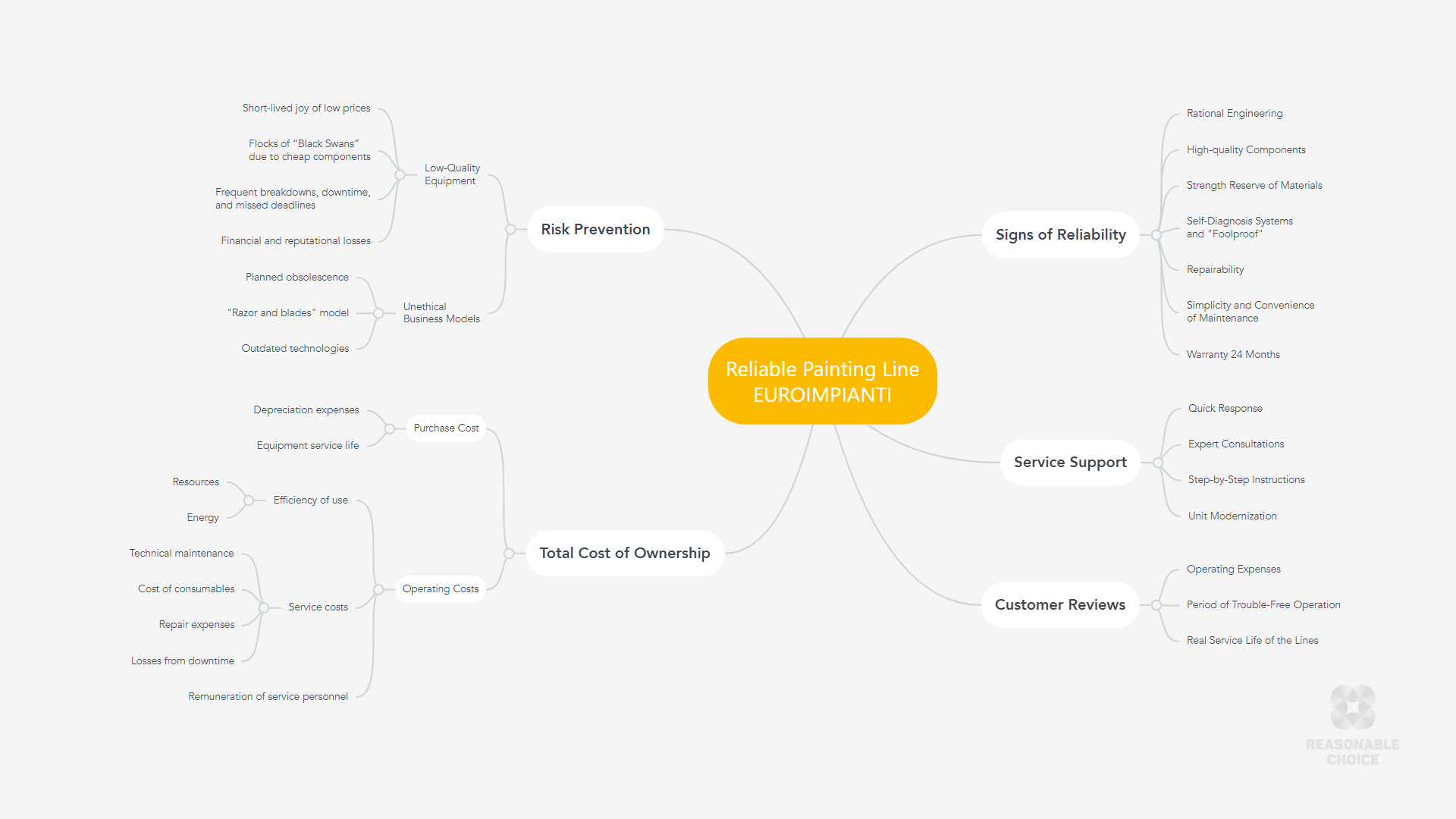

Reliable Painting Line — Long-Term Value

A painting line is complex equipment. Like any complex equipment, the line has a double price — the cost of purchase and the cost of maintenance. If the first price is known right away, then the price of maintenance may turn out to be a surprise — pleasant or not. The total cost of ownership depends on the service life duration, maintenance expenses, as well as the efficiency of material and energy utilization during operation.

Obviously, when choosing a painting line, it is wiser to choose the one that works better and lasts longer. An economical and reliable painting line with a high operational lifespan will provide a competitive advantage for a long period of uninterrupted operation.

The more economical and durable the painting line,

the more profitable it is in the long term.

In an ideal scenario, a professional painting line should provide high quality and minimal cost of coating with uninterrupted operation over 17 - 20 years. But in reality, not every line meets these stringent requirements. Unfortunately, the problems of coating defects and equipment unreliability often become apparent only during operation.

There is good news — the negative consequences of purchasing low-quality and expensive-to-maintain equipment can be anticipated. By wisely leveraging the instructive life experiences of predecessors, you can avoid the pitfalls and buy a reliable painting line.

Risks of Purchasing Low-Quality Equipment

Designing reliable paint lines is no easy task. Competition pushes manufacturers to reduce costs and minimize prices in every possible way. The perennial compromise between "value" and "costs" is often resolved in favor of reducing costs rather than improving the quality and reliability of the equipment.

Dubious moral principles of unscrupulous manufacturers contribute to the development of unethical and blatantly dishonest business models:

- Planned obsolescence, when the production of painting lines uses the cheapest components that quickly fail. Only they do not break immediately, but the next day after the expiration of the warranty period.

- "Razor and blades" model, when equipment is sold at an attractive low price, and consumables and spare parts are supplied at unreasonably inflated prices. At the same time, only original expensive "blades" are suitable for cheap "razors".

- Outdated technologies. Manufacturers may naively delude themselves about the efficiency of their outdated technologies. Often, obsolete equipment continues to be produced due to historical inertia, in spite of the achievements of modern science and technology.

Low-quality equipment will need to be replaced much earlier than the expected service life, which means paying twice. This will result in both financial losses and moral suffering from the shortsightedness of the initial choice.

|

Cheap equipment, in addition to the short-term joy of a low price, also includes a whole flock of "black swans". Failures in operation negatively affect the quality of the painted products and productivity. Due to prolonged downtime, delivery deadlines are disrupted. And the return of defective products has a significant impact on both the profit and reputation of companies. |

To minimize financial and reputational risks, before purchasing equipment, we recommend talking with the owners of factories where painting lines are installed. This will help clarify questions regarding operational reliability and actual service costs. Only objective customer reviews will allow anticipating the consequences of the choice. You will gain an understanding of potential surprises and all the pitfalls.

Questions for Painting Technologists of Powder Coating Lines:

- What difficulties arise in the operation of the line?

- How easy is the equipment to maintain?

- What consumables are used, and how often do they need to be replaced?

- What did you have to modify in the equipment yourself?

- What failures have occurred, how were they resolved, and how did the supplier assist in this?

Painting Line Operating Costs

To assess the economic efficiency of a painting line, it is essential to consider the total cost of ownership. This is the sum of capital costs for acquiring the line and subsequent operating costs to ensure its functionality throughout its useful service life:

Total Cost of Ownership = Purchase Cost + Operating Costs

Purchase cost is just the visible tip of the iceberg; the main costs are hidden under water. Customers encounters them during expensive operation and after the warranty expires.

Operating cost is a particularly important indicator. These are the expenses that will have to be spent for the maintenance and servicing of the equipment throughout its entire lifecycle. Operating costs, in addition to the expenses for maintaining operability, also include the efficiency of resource and energy utilization.

We produce reliable lines with a long working life, which provide high quality polymer coatings at minimal painting costs.Powder Coating Lines

When conducting a comprehensive assessment of operating costs, the following factors are taken into account:

- Costs of consumed resources and energy during operation (efficiency of the painting line, waste and production losses);

- Costs for purchasing spare parts, maintenance (scheduled maintenance), and preventive repairs.

- Labor costs for the maintenance personnel involved in the powder coating section.

- Costs of eliminating accidents and compensation for production downtime (including lost profits).

The indicator of operating costs demonstrates the overall benefit of implementing a painting line — the achievable result and the duration of the economic effect. In other words, the two main indicators are the actual cost of coating and the real service life of the equipment.

|

An efficient and durable painting line has a lower total cost of ownership due to economical resource consumption, reliability and a long service life. The high operational lifespan and efficiency of EUROIMPIANTI are proven by 45 years of successful experience in implementing more than 2.000 painting lines. |

Indicators of Reliability and Durability

Operational reliability is the most important property and criterion for the value of industrial painting lines. The concept of comprehensive reliability includes 3 main qualities — fail-safe, durability and maintainability. This triad will give the user confidence and guarantees a smooth 17 - 20 year service life.

|

Reliability is the property of equipment to maintain its functional characteristics and the quality of the produced output over time. This applies to an extended period of operation, not just within the warranty period. |

High reliability is built in during the design phase and includes a combination of factors:

- Rational engineering solutions to minimize loads on the structure. Precautionary protection of mechanisms from dust and moisture. Seamless compatibility of components working as a unified whole.

- High-quality components with low operating costs and a long service life. Reliable WEISHAUPT gas burners, ABB motors, LOWARA pumps, MAHLE filters, and SIEMENS electronics.

- High strength reserve of materials used for wear resistance, corrosion resistance, and heat resistance (thicknesses and types of steels used). Extension of the working life of quickly wearing consumables.

- Technological reliability. In EUROIMPIANTI lines, for example, if one of the fans for air circulation fails, the intensity of blowing decreases, but the oven remains operational until the motor is replaced or repaired.

- Automatic self-diagnostic systems and "foolproof" protection for detecting and preventing malfunctions. Automation will warn about a long stop of the conveyor with the oven on or remind of the need for technical maintenance and timely replacement of consumables.

- Simplicity and ease of maintenance to maintain operational condition. Service work schedule based on operating hours with clear step-by-step instructions. Simplicity is not only convenience and speed, it is also the elimination of unnecessary work.

- Maintainability — adaptability to quickly restore functionality. Convenient access to all units for inspection and repair. Reduction of maintenance time to increase the useful life of the line.

One of the indirect indicators of the high reliability of a painting line is the warranty period provided by the manufacturer. In the case of highly reliable EUROIMPIANTI lines, the warranty is 24 months for round-the-clock equipment operation.

Expert Service Support

Service support is more than the supply of spare parts. This is a long-term partnership to improve the efficiency of the painting line.

Our primary goal is to achieve a balance between the quality level of the coating and the cost of its application. We will help organize a continuous improvement process — optimizing technology and materials.

Comprehensive service for reliable and efficient line operation includes:

- Expert consultation: We will create an effective communication environment for knowledge exchange, train personnel in the rational operation of the line, and provide technicians with convenient tools for tracking key performance indicators to objectively assess process efficiency and monitor progress.

- Maintenance and repair system: To ensure uninterrupted operation of the painting line, we will organize a system of technical maintenance and a schedule for preventive maintenance. We will make life easier for maintenance staff by providing clear step-by-step instructions with visual diagrams for module disassembly/assembly.

- Unit modernization: We will restore technical specifications or replace worn-out components with new ones that are more economical and durable. We will carry out technological updates to enhance the reliability and efficiency of using chemical reagents, powder coating, and energy carriers.

We respond promptly to all requests because we understand the high cost of production downtime. In case of an emergency, our service engineers will conduct technical diagnostics and assist in quickly restoring the functionality of the equipment.

EUROIMPIANTI coating lines are extremely reliable. They work smoothly day after day for decades. Reliability gives peace of mind and confidence, and also provides operating savings for many, many years.