Minimum Cost of Polymer Coating

After determining the competitive quality of the finishing coating and designing a painting line with an ideal technological cycle according to the individual Technical Assignment, the stage of equipment implementation and achieving the minimum coating cost begins.

On an automated line with a well-established technological process, the cost of painting is 0,5 - 0,7 EUR / 1 m2. Achieving such a result is possible through optimizing resource consumption per unit area — for example, using thin-film coatings and automatic method of applying paint. It can also be achieved by increasing the resource utilization in closed-loop technological cycles — for example, using heat recovery exchangers, chemical solution regenerators, lean powder recovery systems and other options.

Share Distribution in the Powder Coating Cost Diagram

This is the average percentage cost structure distribution in the painting cost per unit area when using an automatic powder coating line.

The percentage distribution of shares in the diagram depends on the cost of materials and energy resources used, as well as on the shape and mass of the painted parts. For example, for heavy, thick-walled products, the share of energy carriers will be greater than for light, thin-walled products, because heating metal-intensive parts requires more energy. Furthermore, the more complex the shape of the products, the higher the consumption rates for paint and chemical agents.

In any case — be it painting simple flat panels, frame parts of complex shapes, or heavy thick-walled metal structures — to minimize costs, it is necessary to use all opportunities to increase the resource and energy efficiency of the technology.

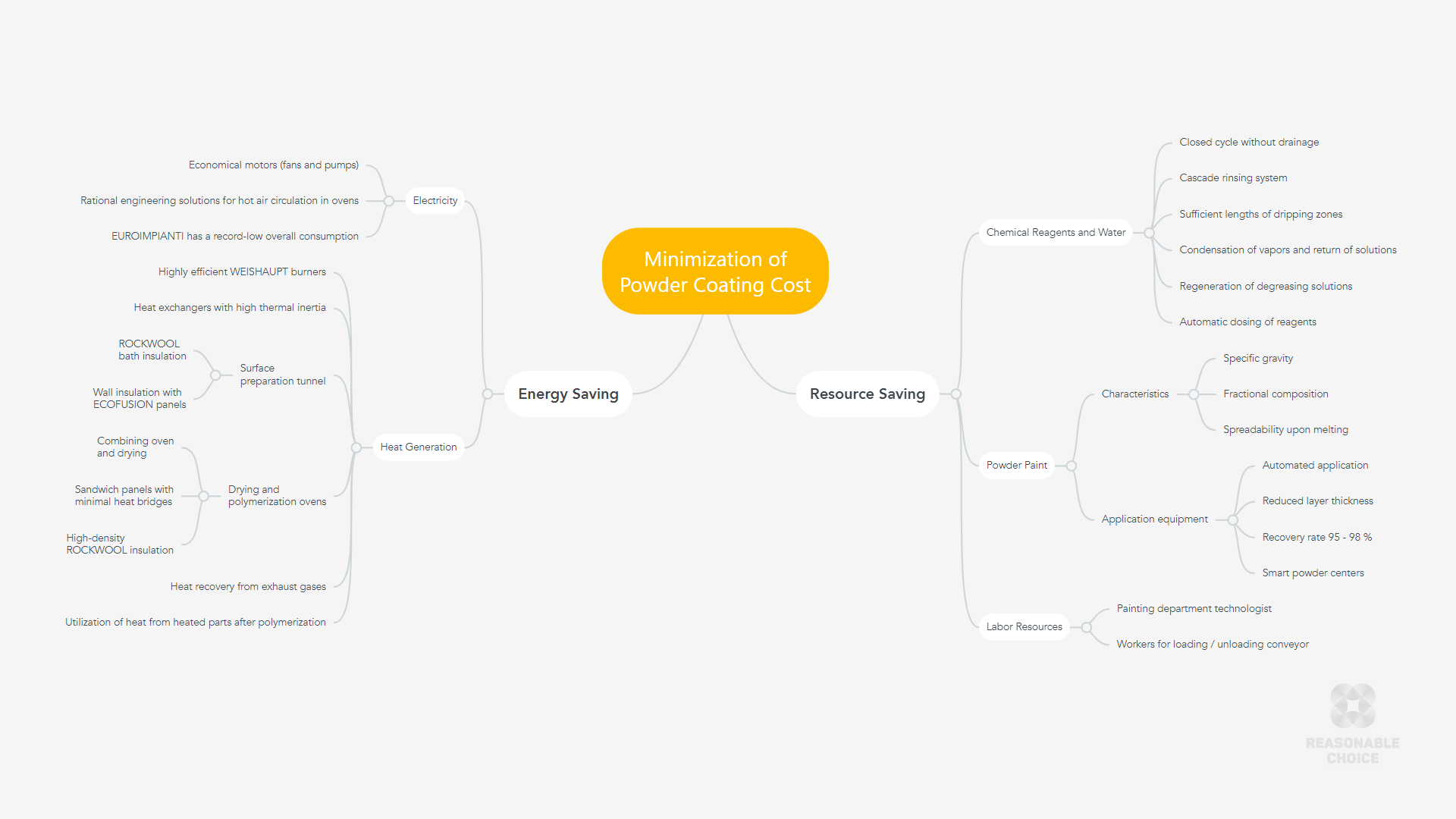

1. Increasing the Resource Efficiency of the Line

Powder coating technology uses chemical reagents, water, powder paint and labor. Let's consider the main ways to optimize and increase the efficiency of utilizing these resources.

1.1 Increasing the efficiency of using chemical reagents and water

The efficiency of resources utilization at the surface preparation stage depends on the correct design of the cascade tunnel and the equipment with additional options.

Cascade rinsing system. Surface preparation tunnels are equipped with an automatic cascade baths replenishment system. The solution level in the operational "hot" baths is replenished by subsequent rinsing baths, where the concentration of reagents increases over time. The last rinsing bath is replenished with fresh water. The cascade system is visually illustrated by the classical 5-stage iron phosphate cycle:

Thanks to the automatic cascade system, a high degree of reagents utilization is achieved in closed cycles without discharging into the sewer. The greater the number of consecutive rinses, the higher the degree of reagent utilization, the cleaner the rinsing water, and thus the higher the quality of the rinsing.

Sufficient lengths of treatment and dripping zones. In addition to the lengths of the active zones in which spraying occurs, it is imperative to provide prechambers and dripping zones. These technological zones prevent the transfer of solutions to adjacent baths.

Correct loading of parts on the conveyor. Parts should be positioned at an angle so that liquids do not accumulate in their recesses but drain into the bath as they pass through the dripping zone. In some cases, it is advisable to install a high-intensity air blow-off module at the tunnel exit. This solution will save wash water and save energy on its evaporation during drying.

Condensation of vapors. All "hot" baths are equipped with vapor extractors with condenser filters, which prevent vapors from escaping outside the tunnel and return condensed solutions to the baths.

Additional options. To optimize the consumption of chemical reagents and reduce losses in the tunnel, it is advisable to use additional options — automatic reagent dispensers, oil separators, filters and regenerators to extend the lifespan of chemical solutions and reduce the frequency of bath fluid changes.

1.2 Increasing the efficiency of using powder paint

Powder paint accounts for the largest share of the cost — approximately 70 - 90 %. This figure primarily depends on the price of the paint and its consumption per unit of surface area.

Characteristics of powder paint. First of all, the consumption rates are influenced by the quality of the powder paint and its physical characteristics, such as:

- Specific gravity of the powder (the lower the specific gravity of the paint, the more economical it is applied due to a thinner layer);

- Fractional / granulometric composition (the minimum thickness of the coating layer is determined by the size of the main fraction);

- Spreadability / flowability of paint during melting (the ability to form a homogeneous layer of melt before polymerization).

Thickness of the polymer coating. To reduce paint consumption rates, the first thing that needs to be determined is the minimum acceptable thickness of the polymer film of the paint coating, which will give the required quality characteristics for the final product.

The film thickness not only determines the paint consumption but also affects the operational characteristics of the coating. When determining the optimal thickness, "more" is not always "better". Since thin-layer coatings are stronger and more elastic compared to thick layers, in which flexibility is reduced.

Depending on the surface structure and required functional properties, the acceptable coating thickness varies widely, ranging from 40 to 150 microns. In protective-decorative coatings, the optimal film thickness is 60 - 80 microns, with an average powder consumption of around 100 - 120 g / m2.

We supply automated lines that provide high quality polymer coatings at minimal painting costs.Powder Coating Lines

Lean painting equipment. To achieve the maximum utilization of powder paint, it is essential to use professional painting equipment:

- Booth with a cyclone or filter recovery system, allowing for up to 95 - 98% powder utilization;

- Automatic spray group with a high powder transfer efficiency and uniform deposition on the surface;

- Powder centers with proportional mixing of fresh and recovered powder.

The primary task of the technologist is to optimally configure spray guns for the entire range of parts to be painted. The main adjustable parameters are the ratio of powder and air, current strength, torch shape and distances from the sprayers to the parts. The use of programmable robotic systems with part shape recognition greatly simplifies this task and allows for stable repeatability of the painting process on all types of products.

1.3 Optimization of labor resources

On a fully automated line, the cost of painting practically does not depend on the salary level of the working personnel. This is because the operation requires a technologist to configure the optimal parameters of the automatic process and low-skilled workers for loading / unloading the conveyor.

|

If the paint is applied manually, then the consumption rates largely depend on the qualifications of the painters. Many of them tend to be overly cautious and apply an excessive amount of paint to avoid leaving unpainted areas. Even incorrectly chosen distances from the spray gun to the painted part can lead to defects — the formation of craters and "orange peel" on the surface. |

Incompetence of painters can be quite costly. Therefore, for a painting production program of 7,000 - 10,000 m2 / month, it is advisable to use automatic spray guns with robotic manipulators. More about the automatic painting method.

2. Increasing the Energy Efficiency of the Line

Energy consumption can be divided into the electricity consumption of motors (pumps and fans) and the energy consumption for generating heat in the "hot" stages of the process.

2.1 Electricity consumed by pumps and fans

An important indicator to pay attention to when comparing competitive offers. Although this cost figure is relatively small, nevertheless, it should not be neglected. Annual energy costs can be quite significant.

The biggest consumer of electricity in the lines is the fans of the paint booth recuperation systems. Engineers pay special attention to optimizing the fan's power and finding a compromise solution to technical conflicts between the aerodynamics of air flows, cyclone geometry, and filter area.

EUROIMPIANTI is a world record holder for electricity consumption. This is achieved through the use of energy-efficient electric motors in recuperation systems and a large number of low-power fans in the ovens.

Depending on the engineering solutions applied and the quality of the motor components, the electricity consumption indicator for paint lines from different manufacturers can vary significantly.

2.2 Main energy carrier for heating stages

Natural gas is used as the energy source for most installed coating lines. A good alternative to using natural gas is generator synthesis gas from wood processing waste (chips and sawdust). In this case, additional investments in gas generating equipment will be required, but this will allow saving up to 70 % on the cost of thermal energy.

In powder coating technology, the energy carrier is used for the following stages:

- Heating chemical solutions to 40 - 60 °C in the surface preparation tunnel during degreasing and phosphating stages;

- Heating parts in the drying oven to 100 - 120 °C for moisture evaporation after surface preparation;

- Heating of parts in a polymerization oven to 160 - 190 °C for the formation and curing of the finishing coating.

Energy consumption is physically dependent on the metal intensity of the items being painted. The heavier and more massive the parts, the more energy is required for their heating, and the larger the share in the cost will be attributed to the energy carrier. This also applies to hooks, the mass of which should be minimized to reduce unnecessary energy costs.

2.3 Efficient use of thermal energy

In addition to the laws of physics and thermodynamics, energy consumption is directly dependent on the technical characteristics and design features of the equipment. EUROIMPIANTI engineers pay special attention to energy conservation, exploring all possibilities for using generated heat and minimizing energy losses:

- Efficient heat generators with a high degree of fuel combustion (WEISHAUPT gas burners);

- Massive heat exchangers with high thermal inertia and maximum heat transfer efficiency;

- Minimization of heat loss from exhaust gases (use of heat recovery from flue gases);

- Highly effective insulation of the tunnel and ovens (the temperature of the outer surface of the oven should not exceed 35 °C);

- Combination of drying with a polymerization oven to save energy and space.

EUROIMPIANTI's unique know-how is the rational use of the energy from heated parts at the exit of the polymerization oven. When the heat from hot parts (heated to 160 - 190 °C) is not simply dissipated in the workshop but is effectively utilized in the drying oven.

Comprehensive Methods for Reducing the Cost of Powder Coating

Attaining the minimum cost of powder coating is an ongoing process of reducing losses and improving the quality of the polymer coating. This is a complex task, the solution of which includes:

- High-tech energy and resource efficient powder coating line;

- Optimal energy carrier, heat generation system with heat exchanger and heat recuperator;

- Use of low-temperature powder paints and chemical reagents;

- Application of special materials for forming thin-film coatings;

- Systematic analysis of the effectiveness of powder coating with tracking of experimental results.

For comprehensive cost reduction in painting, it is beneficial to apply the principles of Toyota's lean manufacturing — the "plan-do-check-act" cycle. With an assessment of quantitative performance indicators that will allow you to track progress towards achieving your goals.

|

The best cost results of 0,5 - 0,7 EUR / m2 are achievable only with mass production and the use of a fully automated conveyor powder coating line. |

Improving the technological process involves continuous collaboration with suppliers of powder paints and chemical reagents. This aims to reduce temperature, processing time, and consumption rates per unit of surface area. Costs decrease with the increase of waste-free powder coating technology.

We guarantee the achievement of the minimum cost of polymer coating — this is the key value of EUROIMPIANTI powder coating lines, providing our clients with long-term economic benefits.