High-Quality Polymer Coating

Powder coating is the final stage of production for most metal products. While the cost of painting represents a small portion of the overall production cost, high-quality polymer coating largely determines the quality of the products and contributes to increased sales in the highly competitive global market.

In a crowded market, the only way to achieve sustainable success is to continually improve product quality. This is the main condition for the survival of companies in competitive evolutionary selection.

The Concept of "Quality" of Polymer Coating

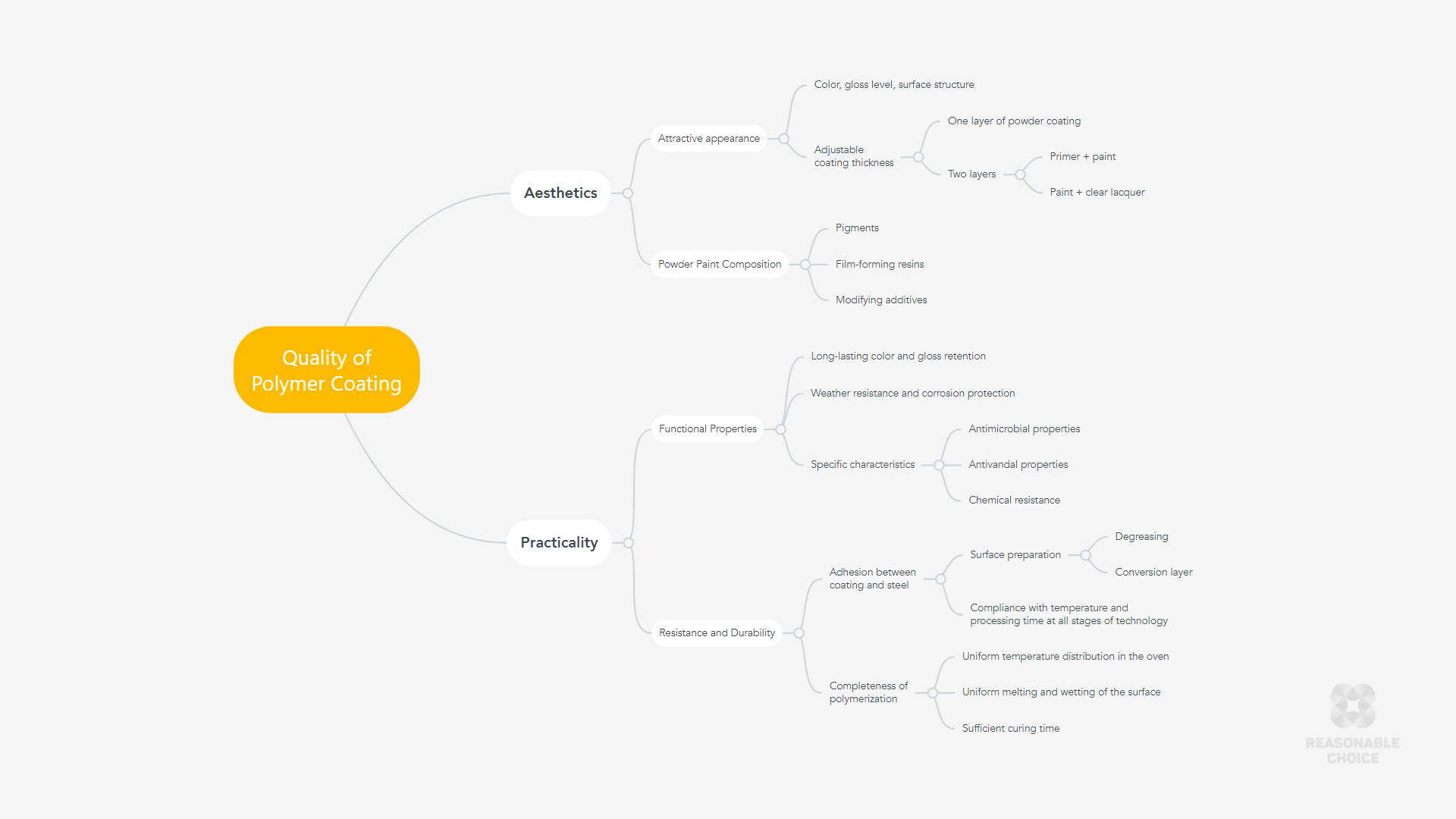

The concept of "quality" of polymer coating can be divided into aesthetic and functional characteristics.

Aesthetic appeal is largely subjective and is determined by consumer preferences and the boundless imagination of designers. Using powder paints you can achieve any color, effect, degree of gloss and surface structure.

The functional component involves corrosion resistance and mechanical durability of the coating. Allows you to maintain aesthetic appeal under conditions of humidity, ultraviolet radiation and other aggressive environmental factors.

The best result in powder coating is achieved at the intersection of these two main characteristics — aesthetic appeal and functional durability of the coating.

|

The quality of a polymer coating is the sum in an equation where one term is beauty, and the other is practicality. Painted products must be both aesthetic and durable: highly resistant to wear, corrosion, ultraviolet radiation and other destructive influences. |

The aesthetics of the coating depend on the quality of pigments, film-forming resins, fillers, and modifying additives that are part of the paint composition. In this case, the paint composition can be modified (customized) depending on individual requirements for appearance.

The resistance and durability of the coating are determined by adhesion, which is the strength of the bond between the metal surface and the polymer film. The strength of adhesion is influenced by the quality of preliminary surface preparation, as well as the ability of powder paint to uniformly melt and wet the metal surface during the polymerization process.

3 Main Factors Affecting Coating Quality

1. Surface preparation — is the most important factor affecting the adhesion strength, resistance and durability of the polymer coating. Processing is carried out in a spray tunnel, where the parts successively go through the stages of degreasing, washing and applying a chemical conversion layer. Read more about surface preparation.

2. Automatic powder application method — ensures uniform coverage with precisely adjustable thickness. Reciprocators with automatic spray guns allow achieving consistent coating quality and repeatability of the process. Read more about painting automation.

3. Complete polymerization in the oven — this requires sufficient time for hot processing and precise adherence to the temperature constant. Well-organized forced air circulation ensures even heat distribution for uniform melting and polymerization of the paint.

We design efficient lines that provide high quality polymer coatings at minimal painting costs.Powder Coating Lines

Coating Quality — as a Competitive Advantage

In a free market, product quality is the main factor of competitiveness. The finishing coating must satisfy the requirements of consumers to the maximum extent — this applies to both appearance and protective anti-corrosion properties.

"The bitterness of poor quality remains long after the sweetness of low price is forgotten".

Benjamin Franklin

A good starting point is to investigate consumer needs and research products available in the market. When developing new types of products with a higher level of quality, it is necessary to use all possible ways to improve operational and aesthetic characteristics.

Depending on the type of product and the category of goods, competitive advantages can be represented by such characteristics:

- Weather-resistant coatings, allowing for product use in the most aggressive coastal marine climates with intense sunlight, high humidity, and salt-laden air.

- Anti-vandal coatings that streamline the restoration and cleaning process. With high resistance to solvents, which are used to clean surfaces from graffiti and glue.

- Antibacterial/antimicrobial coatings, opening up possibilities for product application in various public facilities (stores, hospitals, sports complexes, etc.).

- Chemically resistant coatings to alkalis, acids and other aggressive substances. Such coatings are used in the production of laboratory and industrial equipment.

Consumer demands are on the rise, and along with them, the need for convincing evidence of high product quality is also on the rise. The best guarantees are the results of objective tests and international quality certificates.

Basic Methods for Assessing the Quality of Powder Coating

To measure the decorative characteristics and physical and mechanical properties of paint and varnish coatings, there are reliable instrumental methods and instruments.

Decorative qualities are measured using optical instruments for determining color and gloss. Tests for resistance to aggressive atmospheric factors are conducted both under natural outdoor exposure and through accelerated laboratory methods in specialized chambers (salt spray chambers, heat/cold chambers, and UV radiation chambers).

The world standards for testing coatings for weather resistance are:

- Natural exposure testing in Florida, in an aggressive subtropical climate with the maximum number of sunny days per year.

- Salt spray chamber testing, simulating the "concentrated" impact of destructive atmospheric factors.

The results of outdoor and laboratory tests are compared and calibrated with each other. Therefore, thanks to accelerated laboratory tests, it is possible to predict with high probability the performance qualities — the durability and functional resistance of the paint and varnish coating under real operating conditions.

Only achieving certified quality standards opens up the possibility of entering the world market. Quality certificates such as ISO, ASTM, NACE, AAMA, and QUALICOAT demonstrate the high aesthetic and functional characteristics of the coating, enhancing the consumer value of the painted products.

Testing in a certified laboratory equipped with modern instruments for measuring and controlling regulatory parameters allows abstract "quality" to be expressed in an objective quantitative form. Successful test results enable obtaining certificates of international quality standards accepted for various product applications.

Methods for Improving the Quality of Painted Products

When offering a powder coating line, we take into account the category of the products to be painted, the conditions of their use, and the required service life. New product quality requires the use of new materials and production technologies.

|

Achieving high-quality powder coating is impossible without the implementation of modern powder coating technologies and the use of the best powder paints and chemical agents. |

Improving the quality of painted products is a complex task, the solution of which includes:

- Correct choice of chemical surface preparation cycle with the formation of a protective conversion layer;

- Quality materials: the type and composition of chemicals and paints that can be customized for each specific application;

- Coating thickness and the number of layers (two coats can be applied — with a preliminary primer or with a clear lacquer);

- Automatic painting method ensuring uniform coating thickness and consistent process repeatability;

- Use a professional powder coating line and adhering to ideal technology at all stages of coating formation.

In the technological process of applying powder coating, adhesion, degree of curing, and film thickness are entirely controllable parameters. We will assist in implementing a scientific method of experimentation for tracking positive results to enhance the quality of the polymer coating.

The use of our powder coating lines is guaranteed to improve the quality of the polymer coating and the consumer properties of the painted products. And higher competitiveness of products will certainly ensure increased sales and expansion of sales markets.